You are here:home > Industry news > Pruduct's Detail

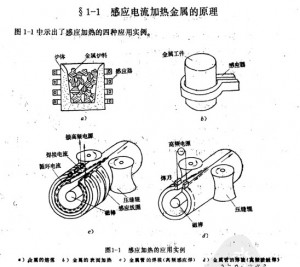

The core and the application of high frequency induction heating furnace technology

Along with the electronic technology rapid, the original use of high frequency induction furnace furnace power feelingbroad has been set solid state circuit static variable frequency power supply gradually sweep. High frequency induction furnace has been widely used in cast iron, casthomework and she agglutination and so on, and because it issuitable for batch (batch) work on molten metalsolidification and stirring force adjustable characteristic,make its application in steel smelting and nonferrous metalconsolidation heat-resistant alloy has a shrinking.

Induction furnace is the application of electromagnetic induction principle to transfer the energy to the charge of metal, electricity can transform into a resistance heating mode heat energy to have a fever and melted metal charge.Power solid state medium frequency furnace is a fixedfrequency power supply for power semiconductor devices,usually a AC-DC-AC inverter and AC – DC inverter two. Soto feel heating, must meet two conditions: one is the use of alternating current; two is the required heating the object is metal materials.

High frequency induction heating furnace according to the organization, the crucible type (i.e., occasionallyfurnace) and groove type (i.e., deliberately furnace) two categories, the first is used, heat preservation andpouring. While high frequency furnace frequency range to0.05-10KHZ, mainly applied to the steel and non-ferrous metal smelting and heat preservation. The use ofintermediate frequency electric furnace interests feeling:

(1) high power density, high speed, convenient batchmelting, suitable for energy saving of aggregation;

(2) using sensitive and convenient operation, suitable for the constantly changing the agglutination metal varietiesplace;

(3) determines the power frequency, the intermediate frequency electric furnace is more suitable for lightfeeling of non-ferrous metal melting;

(4) because of the high power density, no phase equilibriumapparatus, small civil charges;

(5) the intermediate frequency electric furnace molten metalfeeling exists only a “overheating” situation, which in thefield of metallurgy popular;

(6) way of automatic control equipment, if feel frequencyfurnace operation to the diagnosis and monitoring of furnace condition can be obtained by summing machine, greatly reducing the rest strength, improve the task to.

High frequency induction furnace is high, has the function of adjustable frequency, low noise, small size, light weight, simple installation, maintenance simple controlmany benefits, I plant began to application of intermediate frequency furnace to find gold and silver recovery processproduction in 2001, and got very good effect, in practicehave accumulated good teaching. At present in the gold and silver beads, condensation, quenching effect to accept,alloy melting, assaying and sampling and other aspects ofthe work for suitable for their own color, successfullycompleted more streamlined students create task. However,the use of intermediate frequency electric furnace in recent years feeling, also have some questions. If according to the material difference resolution crucible materials,models; selection of lining and refractory raw materialsand furnace building skills; improve work conditions such as revocation of dust, noise and temperature rise; silicon rectifier and thyristor converter equipped with task occurs when the harmonic current and harmonic. The pollution of the grid, and how to improve the power factor and so on. As usual if feel furnace manufacturers equipment production,has a variety of concerns, such as cooling water pressure is low, the water temperature is too high pressure and temperature concerns, over current and short of concern for the people, owe voltage concerns, lack of pity, cruciblefurnace leakage and main circuit grounding annotation etc..

But we should also pay attention to the following pointswhen in use:

(1) the boot operation before should first visit the value of the supply voltage and the three-phase equilibrium;

(2) the connection of electrical contact search carefully,especially the SCR reactor, water-cooled cable electriccapacitor, etc.;

(3) open water circulating cooling water system to check the host, furnace body water operation and adhere tocertain;

(4) lining sintering and baking to reduce electromagnetic stirring and persuaded the corrosion to the lining, to low power operation (Fei Teng voltage) for a period of time,the heating furnace homogeneous;

(5) in normal operation, but also should patrol operationequipment, rated water temperature in each Road branch,there are instructions can also be composed of sound changedecisive equipment can be normal;

(6) may be appropriate to reduce high frequency furnace to discontinue the use of cooling water, but not closed cooling water, otherwise the coil and lining heat insulating layergrinding;

(7) in the melting dominate, no (A) found lining of serious damage, continued melting; (B) cooling water stop running; (C), the furnace body is equipped with no good grounding; (D) in electric power and do not have safeprotection when charging, French ramming solid charge,sampling, adding a small amount of alloy, temperature, slagand other homework; although, daily maintenance and testwork by medium frequency induction furnace as should pay attention to equipment, in particular to be anti moisture,acid proof, alkali gases erosion on electronic components,send all kinds of hazards, resist the affairs and ensuresafety in production for a long time.